Non Return Valves

Non-return valves are safety devices to prevent backfeeding of gases. WITT non-return valves protect plants, pipelines and outlet Non-return valvepoints against reverse gasflow. They can also be used in accordance with EN 764 section 2 in applications where the maximum temperature does not exceed 70° C (158° F).

Witt have a significant range of Non-Return Valves with thread connections from 1/8″ BSP to flange DN 200 and flows up to 26,800 m3/h (rated in air) (NV2000). They are suitable for a range of technical gases (for acetylene, NRV 650 only). The sophisticated valve technology of WITT non-return valves provides small pressure drops making them also suitable for applications with smallest opening pressures. A high-quality sealing system with elastomeres prevents leakages and dirt filters at the inlet point assure long service life of the non-return valves.

Benefits

* the non-return valves prevent backfeeding of gases which could lead to flammable mixtures being formed

* minimum pressure drops result from low opening pressures. eg. Model NV 200 is approximately 4 mbar (0.058 psi)

* the valve mechanism is protected by a mesh filter

* the valves are suitable for use with most non-corrosive gases

* the spring loaded valve is not affected by gravity and may be installed in any position

Maintenance In common with safety equipment non-return valves should be tested at least once a year for function and body leak tightness. Testing equipment is available on request. Witt non-return valves should only be serviced by Witt or approved repairer. The dirt filters however can be replaced by the user.

WITT non-return valves in thermal processing plants

WITT non-return valves conform to EN 746-2 and are particularly suitable for use in thermal processing plants. The low opening pressure of only 3 mbar and the high flow rate provide ideal protection for burner systems and prevent gas backflow and flashbacks.

WITT non-return valves can be installed in the air or oxygen line as well as in the fuel gas supply, thus reducing acquisition and storage costs. WITT non-return valves are 100% tested to DIN EN 5175-2 prior to delivery and offer the highest level of safety.Non-return_valves_thermoprocessing

Safe biogas plants with WITT gas non-return valves

In the air delivery lines to fermenters and biogas lines, WITT gas non-return valves are also characterised by their ultra-low opening pressures. WITT stainless steel valves for operation in biogas plants allow an air flow only in one direction and thus avoid unwanted and dangerous gas mixtures. Due to their low pressure losses, the use of small pipe cross-sections is possible, which reduces the operating costs for the compressor performance. WITT check valves are particularly leak-tight and therefore particularly safe. The valves are 100% tested and conform to DIN EN ISO 5175-2. The use of stainless steel in the gas return valves ensures a long service life, as these materials are extremely resistant to corrosion. They can also be retrofitted into existing air and gas supply lines.Non-return_valves_biogas

Showing 1–9 of 15 results

-

Non-Return Valve 600H-ES. MWP: 40Bar, ½”, 3/4″ & 1″BSP

-

Non-Return Valve 70 / 70U. MWP: 16/10Bar. 3/4″, 1″, 1¼” & 1½”BSP

-

Non-Return Valve 800-ES. MWP: 300Bar. ¼”NPT

-

Non-Return Valve NV100. MWP: 25Bar. 1/8″, ¼”, 3/8″BSP

-

Non-Return Valve NV200. MWP: 16Bar. ½”, 3/4″, 1″BSP

-

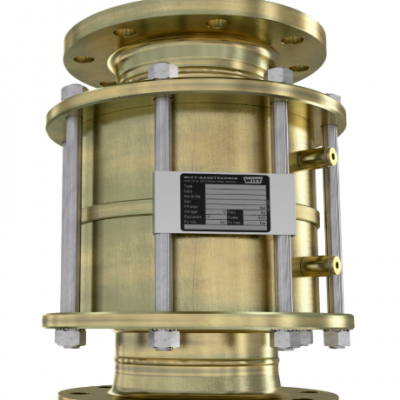

Non-Return Valve NV2000. MWP: 10Bar. DN 80 -200

-

Non-Return Valve NV300. MWP: 16Bar. 1″, 1¼”BSP

-

Non-Return Valve NV400. MWP: 3Bar. 1½”, 2″BSP

-

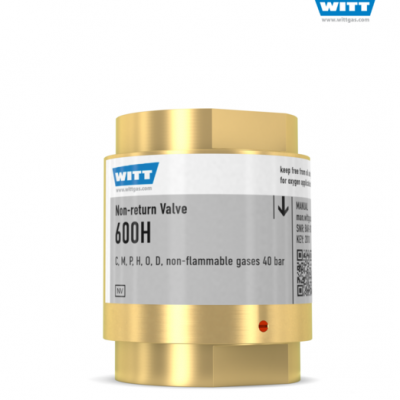

Non-Return Valve NV600H. MWP: 40Bar. ½”, 3/4″, 1″BSP