Gas Fluxers

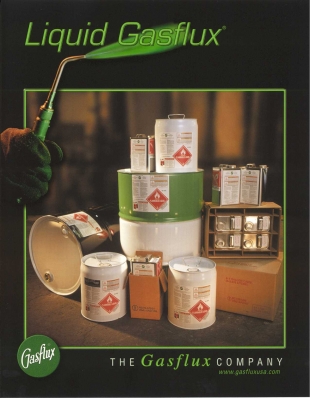

The Gasflux Process is a means for adding flux in a vapor form to any fuel gas. The resultant superior fluxing and wetting action encourages brazing alloys to flow evenly and follow the flame smoothly. The Gasflux Process produces joints of optimum strength and outstanding appearance while minimising post braze cleanup. Productivity increases at reduced costs.

The Gasflux Process utilises a Gasfluxer for mixing liquid Gasflux with the fuel gas. The Gasfluxer consists of a mixing chamber and reserve tank. It can be connected into any standard brazing torch operation in less than 5 minutes. A single Gasfluer can also be installed for multiple torch stations as well as automatic brazing equipment.

Fuel gas is introduced into the Gasfluxer mixing chamber and is allowed to bubble through the liquid Gasflux. A simple needle valve controls flow for proper flux volume. A bright green flame indicates the flux is in the flame.

NGP are Agents for The Gasflux Company, USA.

Showing all 6 results