Gas Fluxers

-

Vendor: The Gasflux CompanyOur C-04® Nickel Bronze is a specially formulated low fuming copper/zinc alloy with additions of nickel, manganese and iron to improve flow and increase strength. Silicon is adjusted to limit zinc fuming and improve flow characteristics. It is most commonly used on steels, copper, nickel...

- From $2.55

- From $2.55

- Unit price

- per

-

-

Vendor: Niche Gas Products

Gasflux, Type 'H', Black, High Temp Brazing Paste, 454gm

- $30.00

- $30.00

- Unit price

- per

-

Vendor: Niche Gas Products

Gasflux, Type 'U', White, Low Temp Silver Brazing Paste, 454gm

Type “U” is a finely ground, all-purpose paste flux for brazing with silver alloys. It readily dissolves unwanted oxides and inhibits further oxidation. Type “U” provides the clean surface needed for the ready flow of molten silver alloys.- $30.00

- $30.00

- Unit price

- per

-

Vendor: Niche Gas Products

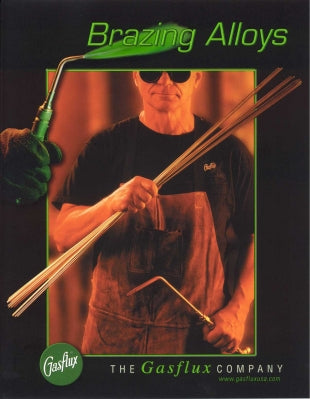

Gasflux, Type 'B', Blue, High Temp Bronze Brazing Paste, 227gm

Our Type 'B' paste flux is used exclusively for bronze and nickel silver applications. Type 'B' is a consistent, homogenous paste that offers an alternative to powders or flux-coated rods. It contains no fluorides and is non corrosive.- $25.00

- $25.00

- Unit price

- per

-

Vendor: Niche Gas ProductsThere are 4 Gasfluxer models to choose from, however the most popular model is 69 The Gasflux® Process utilizes equipment to dispense Liquid Gasflux® with the fuel gas. The Gasfluxer® consists of a mixing chamber and a reserve tank for flux storage. Our model 69...

- $1,980.00

- $1,980.00

- Unit price

- per

-

Vendor: Niche Gas ProductsNGP stocks 19 ltr and 3.8 ltr Type ‘W’ Liquid Gasflux® Type ‘W’ is our universal liquid Gasflux® for both silver and bronze brazing. It is suitable with almost all applications for the brazing of copper, brass, steel, stainless steel, cast iron and carbide....

The Gasflux Process is a means for adding flux in a vapor form to any fuel gas. The resultant superior fluxing and wetting action encourages brazing alloys to flow evenly and follow the flame smoothly. The Gasflux Process produces joints of optimum strength and outstanding appearance while minimising post braze cleanup. Productivity increases at reduced costs.

The Gasflux Process utilises a Gasfluxer for mixing liquid Gasflux with the fuel gas. The Gasfluxer consists of a mixing chamber and reserve tank. It can be connected into any standard brazing torch operation in less than 5 minutes. A single Gasfluer can also be installed for multiple torch stations as well as automatic brazing equipment.

Fuel gas is introduced into the Gasfluxer mixing chamber and is allowed to bubble through the liquid Gasflux. A simple needle valve controls flow for proper flux volume. A bright green flame indicates the flux is in the flame.

NGP are Agents for The Gasflux Company, USA.